This content is reproduced with the kind permission of the original author Mike Brenner and was originally published at Stockopedia

- The Team

- 2D-Tech – www.2-dtech.com

- Cambridge Graphene Ink – http://www.cambridgegraphene.c…

- Scalable VRS product technology and manufacturing

- VRS Application and Product Development

- End of life, Toxicity of graphene in products

- Sales Distribution

- Financials

- Summary

Versarien Overview

Versarien plc (£VRS), is an advanced engineering materials group. Leveraging proprietary technology, the Group creates innovative engineering solutions for its clients in a diverse range of industries. Versarien has five subsidiaries operating under two divisions:

Thermal and Hard Wear Products

- Versarien Technologies Ltd. which produces thermal copper/aluminium and other aluminium products. www.versarien-technologies.co.uk

- Total Carbide Ltd, a leading manufacturer in sintered tungsten carbide for applications in arduous environments such as the oil and gas industry. www.totalcarbide.com

Graphene and Plastic Products

- 2-DTech Ltd, which specialises in the supply, characterisation and early stage development of graphene products. www.2-dtech.com (Spun out of the university of Manchester in 2015)

- Cambridge Graphene Ltd, which supplies novel inks based on graphene and related materials, using patented processes and develops graphene materials technology for licensing to manufacturers. www.cambridgegraphene.com (Spun out of the University of Cambridge in 2017)

- ACC Cyroma Ltd, which specialises in the supply of vacuum-formed and injection-moulded products to the automotive, construction, utilities and retail industry sectors

A 2017 presentation at the SHARES conference by Neill Ricketts CEO giving a good background on Versarien and future graphene applications they are working on – https://www.youtube.com/watch?v=UTzntFw-EgU&t=1102s

… and here are some useful podcast interviews with Vox Market Podcasts where Neill Ricketts is interviewed a number of times around their interim results, collaborations they have announced and China JV https://www.voxmarkets.co.uk/company/VRS

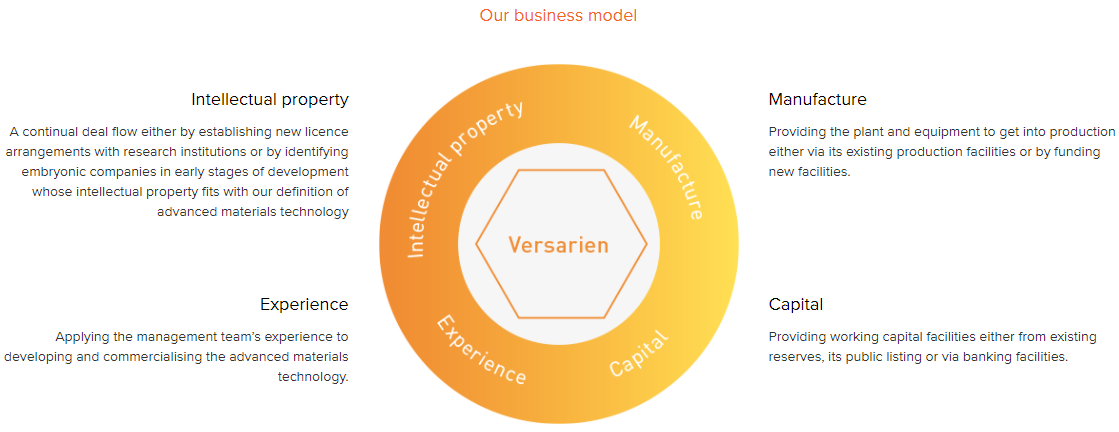

Business Model

The Team

VRS leadership are a very well-respected team – anyone can see from their profiles the huge amount of relevant experience and are well connected to the relevant industries for commercialising advanced materials http://www.versarien.com/about-us/board-directors/. There is a lot more I could cover here about Ian Grey they chairman, Neill Ricketts the CEO and Chris Leigh the CFO, but it should come out over the next pages.

- University of Manchester were partnered with Morgan Advanced Materials (A £1billion listed business £MGAM) who helped them with the original research into a commercial manufacturing process see

- 2014 – http://www.morganadvancedmaterials.com/en-gb/media-centre/press-releases-morgan-issued/the-university-of-manchester-partners-with-morgan-advanced-materials-for-graphene-development/

- 2015 – http://www.morganadvancedmaterials.com/en-gb/media-centre/press-releases-morgan-issued/morgan-conducts-first-graphene-experiment-at-university-of-manchester/

- It didn’t make sense to me how VRS managed to pick out 2 world leading technologies in Graphene with 2D-Tech, Nanene and Cambridge Graphene Ink. Some observations:

- The Versarien team skill set

- Passionate engineers, materials developers but also entrepreneurs.

- Success of VersarienCu™ their advanced copper foam materials business spun out of University of Liverpool to provide thermal management – http://www.versarien-technologies.co.uk

- Proven experience in

- advanced materials

- licensing & commercialising IP from universities

- aerospace, F1, composites, batteries, plastics

- building start-ups to commercialise them

- moving customers from concept to production

- product development – from the lab to manufacturing products for customers

- Understood the need for independent data to build trust with customers

- They are commercial, strike good win-win deals both to license IP and to sell it!

- They have always followed the same process of contact, NDA, Collaboration, Testing, Order and you can see the methodical progress they make with partners

- Massive amounts of tenacity, confidence and belief. (Background to setting up VRS: http://www.eurekamagazine.co.uk/design-engineering-features/interviews/interview-with-neill-ricketts-will-battrick/59493/)

2D-Tech – www.2-dtech.com

Based in Manchester, 2-DTech is a development company born from the group that first isolated graphene at the University of Manchester. 2-DTech provides world class graphene materials, characterisation services and consultancy into an exceptionally active market.

- Versarien acquired 85% of 2-DTech in April 2014 and now working side by side with the University of Manchester, its mission is to commercialise graphene by integration into real world applications, creating significant socio-economic benefit.

- A Feb 2015 presentation of the 2D-Tech business – lots of interesting detail https://www.youtube.com/watch?v=T0TfygrekXo

Background to the deal

- Versarien did not go after the tech. 2D-Tech MD was run by Mark Shepherd the founder of £XAAR. On behalf of the University of Manchester he sought them out as a desired partner to take it to its full commercial potential.

- The University of Manchester was under pressure by the UK government for failing to commercialise graphene. They struggled to find UK partners and had a major failed attempt with an international player:

- Sept 2013 – Dr Chung Ping Lai, Chief Executive Officer for Bluestone Global Tech, One of the world’s largest graphene manufacturers agreed a £5m collaborative research partnership to open its European base at The University of Manchester http://www.manchester.ac.uk/discover/news/university-attracts-major-graphene-manufacturer-to-manchester/

- University of Manchester physicist Andre Geim told the select committee that the company “burned US$50 million” trying to get graphene products to market and “went bust, essentially”. Lai immediately founded BGT Materials http://bgtmaterials.com/about.php and signed a contract to pay the University of Manchester £3 million for collaborative work. By mid-2014, however, BGT Materials was strapped for cash, and asked the university to exchange its debt for shares in the company. In 2015, the University of Manchester took an 18% share in the firm, which cleared the debt

- Graphene Lighting, http://graphenelighting.co/#overview a subsidiary of BGT Materials that aimed to commercialize a lightbulb that uses graphene to carry heat away from a light-emitting diode (LED) to improve its efficiency. But the lighting firm was cold-shouldered by UK investors, eventually getting funding from investors in Canada. http://www.nature.com/news/uk-graphene-inquiry-reveals-commercial-struggles-1.19840#/casestudy

- The University of Manchester was under pressure by the UK government for failing to commercialise graphene. They struggled to find UK partners and had a major failed attempt with an international player:

- The University of Manchester know Neill and they knew what he is like, so they dragged him up there to convince him graphene was the way forward.

- Once fully explained to them they thought it was a fantastic opportunity but were acutely aware of all the false rubbish out there which will have been explained to them by the University of Manchester hence why they haven’t made much noise so Versarien set about working on the tech and testing the end product before shouting about it.

- Proof 2D-Tech Graphene meets the new ISO standards – It may not have worked, until the process was complete they would not know so this is why Neil refers to “an excited team” in his RNS about 2017 results because it does work and they know with the ISO standards that 99% of graphene out there doesn’t and they can easily explain why to customers.

- All these big names can see VRS have a graphene that transforms products, that they are experts and have the world leading graphene authorities and Universities backing them.

Graphene Manufacturing

- 2D-Tech can create all types of graphene via the 3 main production methods – mechanical exfoliation (grinding), sonification and chemical vapour deposition, and they can create all 4 forms of graphene however they have chosen to focus on the most commercially viable process

- Why has 2D-Tech developed this technique?

- Blue-chip clients have been looking to 2D-Tech to develop a process to produce graphene with a high chemical purity in as a few layers as possible.

- Looking for the graphene to have all the intrinsic properties that the material is known for: super strength, exceptional conductivity and virtually no mass.

- Clients are very well aware of what this wonder material could potentially do for their products but are looking to 2D-Tech to provide them with a reliable and cost-effective source of raw material.

- Working with many clients, from industries as diverse as military, medical and consumer products, requiring access to high quality, cost effective graphene

- Blue-chip clients have been looking to 2D-Tech to develop a process to produce graphene with a high chemical purity in as a few layers as possible.

- Major advance in scalable graphene production – Feb 1st,2017 https://www.nanene.com/news/major-advance-scalable-graphene-production/

- 2-DTech, made a major advance in graphene platelet production, to accelerate potential commercial applications for graphene and graphene products.

- Building on techniques originating from University of Manchester, refined by University of Ulster and 2-DTech, this patented process involves a mechanised exfoliation process in which a strong shearing force is applied to the surface of the graphene layers.

- Versarien has now developed its own proprietary graphene production technique founded upon a licenced process from University of Ulster which offers numerous advantages over the conventional graphene manufacturing solutions currently on the market.

- A fundamental step forward in producing graphene using a patented, commercially viable production method

- This process is no more complex than existing production techniques thereby providing customers greater product flexibility. Parameters such as secondary processing and dispersion mediums and methods can be set to meet end-use application requirements e.g. composites to batteries. Different solvents can be specified, a wide range of concentration levels can be selected from, as well as different product forms either a liquid or powder.

- Many different types of 2D and nano materials can be produced using this process such as Boron nitride with proof being the CPI tender win

- To make it commercially viable 2D Tech had to undergo a radical rethink on how to go about things. This includes everything from manufacturing processes, product design, and creating new technologies that weren’t possible before. They need to make sure that production capacity of the raw material is built in line with customer expectation and commercial viability, and this really comes down to having a reliable, repeatable and cost-effective method to produce it.

- Tested by the Versarien team as well as by a number of independent testing houses e.g. National Physics Laboratory.

- Nanene – https://www.nanene.com/ – Versarien created their own brand of graphene to differentiate in the marketplace from all the graphene that didn’t meet ISO standards

- The patented process that is used to manufacture Nanene produces high quality graphene nano-platelets with a majority of sub 10 layers and a significant number of sub 5 layers material.

- This gives Nanene its incredible physical and mechanical properties performance benefits, the chemical properties gives it the ability to mix in other materials.

- The quality of this process has been independently verified by several leading United Kingdom universities and Versarien has a portfolio of independent test results for applications they have created for partners

- To quote the CEO in a recent vox market podcast about Nanene “the scale and opportunity is staggering,” and “this material will significantly impact society”

- Use Cases for Nanene Enhanced Applications – This link to the Nanene trademarks gives an idea on the breadth of potential applications https://trademarks.ipo.gov.uk/ipo-tmcase/page/Results/1/UK00003199581

- Chemicals (industrial-); carbon; graphene; resins; graphite; natural graphite; pyrolytic graphite; expanded graphites; absorbent graphites; artificial graphite for industrial purposes; graphene for research and industrial purposes; carbon for research and industrial purposes; plastics, unprocessed; carbon and allotropes thereof; carbonates; unprocessed and artificial resins; unprocessed plastics; carbon fibre composites; carbon fibre composite for use in manufacturing sports equipment; carbon fibre composite for use in 3D printing and apparatus for 3D printing; printing chemicals; fibre reinforced composites for use in manufacturing of sports equipment; graphene enhanced plastics for use in manufacturing of fibre reinforced composites; graphene enhanced adhesives; graphene enhanced heat transfer fluids; graphene enhanced heat transfer solids; heat transfer; heat transfer substances; chemicals for use in the semiconductor industry; semiconductor cooling substances; liquid cooling substances; liquid cooling materials.

- Preservative against rust; hydrophobic coatings; abrasion resistant coatings; moisture ingress protective coatings; matrix additives for the purpose of surface protection; matrix additives for the purpose of hydrophobic properties at its surface(s); coatings for the purpose protecting the parent material by transmission of electrical energy along surface and not through parent material; anti foul coatings; hydrophobic materials.

- Printing machines; 3D printers; 3D printing pens; printing apparatus and equipment; machine parts; machine tools; engines; engine drive shafts; marine engines; boat engines; airplane engines; aircraft engines; jet engines; gas engines; engine components; turbines; hydraulic turbines; sub-sea tidal turbines; wind turbines; gas turbines; turbine vanes; turbines for power generation; turbine blades; turbine shafts; blades for aircraft turbines; parts and fittings for the aforesaid goods.

- Apparatus and equipment for heating and cooling; appliances for heating; heat accumulators; heat collectors; heat exchangers; heat exchangers [for chemical processing]; heat generating apparatus; regenerators (heat-); solar heating apparatus; temperature control apparatus and equipment; thermal fluid heaters; water coolers and heaters; cooling apparatus; cooling apparatus for liquids; cooling elements; water cooling apparatus; parts and fittings for all of the aforesaid goods.

- Vehicles; motor vehicles; cars; bicycles; motorcycles; motor yachts; motor boats; motor homes; motor caravans; lorries; snow sleds; snowmobiles; trucks; helicopters; planes; fixed wing aircraft; engines for land vehicles; helicopter rotors; helicopter blades; tail rotors for helicopters; structural parts and components for helicopters; aeroplane rotors; aeroplane blades; fan rotors; fan blades; wings for aeroplanes; structural parts and components for aeroplanes; vehicle body panels; turbines for land vehicles; turbine vanes being parts of land vehicles; parts and fittings for the aforesaid goods.

- Technical plastics; semi-processed plastics; semi-processed synthetic and natural resins; plastic compounds; carbon fibre; carbon fibre composites; carbon fibre composite for use in manufacturing sports equipment; carbon fibre reinforced synthetic resins for use in manufacture; 3D printing; semi-worked thermoplastic filaments used for 3D printing; semi-worked PLA filaments for use in 3D printing; semi-worked ABS filaments for use in 3D printing; insulating material; insulating materials; cooling materials; heating materials; heat transfer materials; polymer resin fibres [other than for use in textiles]; sealing materials; gaskets and seals; semiconductor cooling substances.

- Apparatus and equipment for training, sport, gymnastics, exercise, rehabilitation and fitness; gymnastic and sporting articles; sports equipment; balls for sports; sledges; sports bats; sports racquets; tennis rackets; frames for tennis raquets; frames for raquets; golf clubs; human input devices; touchscreens; cases and bags adapted for sporting articles or sporting equipment; playthings; toys; parts and fittings for the aforesaid goods.

- Printing; 3D printing; manufacturing of graphene from its raw constituent materials; blending of raw materials to create graphene enhanced materials; information, advisory and consultancy services relating to the aforesaid.

- Scientific and technological services and research and design relating thereto; industrial analysis and research services; research and development of chemical processes for obtaining chemicals and substances including graphene, carbon, carbon fibres and carbon composites; manufacturing of graphene from its raw constituent materials; blending of raw materials to create graphene enhanced materials; information, advisory and consultancy services relating to the aforesaid.

- Protecting Nanene IP – Outside of usual legal agreements with partners, patents on their process to create Nanene and the ability to sue Versarien have a number of checks & balanced

- The ionic liquid referred to in this article on the original patented process is the recipe / trade secrets that VRS hold and would provide to partners to manufacture with https://www.ulster.ac.uk/news/2012/january/revolutionary-breakthrough-by-ulster-scientists

- This means you can have the graphite, have the machine, but need the specific liquid from VRS to manufacture Nanene. This is the equivalent of Coca Cola and their trade secrets recipe and becomes very applicable when looking at how VRS protects its Nanene IP when they manufacture around the world. http://www.inventionresource.com/index.php?option=com_content&view=article&id=37

- The partner wouldn’t have the credibility of being backed by the University of Manchester and having any of the new applications / products approved by them – this stamp of approval matters!

- A clever aspect of the China JV is to have collaborative research between the University of Manchester and the Chinese universities to explore graphene uses … adds a layer of international credibility that must be maintained to keep the open partnership working

- Finally, Nanene is just one form of graphene that VRS can produce, and they have another 2000 2D advanced materials that are being developed and commercialised by the University of Manchester and University of Cambridge so they can stop all future access to offending parties.

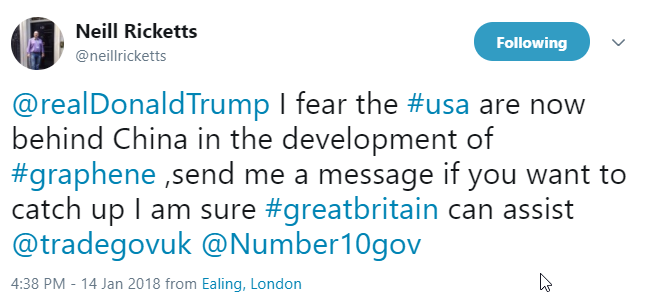

- An interesting couple of tweets from NR the CEO https://twitter.com/neillricketts/status/955048032353079296 makes me think that sharing their IP through licenses and JVs will help speed along innovation, creating greater and greater opportunities for graphene enhanced applications, which Versarien can realize by executing well. I think that NR is confident in Versarien’s ability to execute, has the unique flywheel (more later) and recognizes that patents slow them down as well as sharing the crown jewels once granted – today it’s a black box to competitors which is why they have a significant advantage. The more graphene enhanced applications in the market, means more overall opportunity for Versarien graphene products that they believe are the best in the market which makes Versarien more valuable.

- The ionic liquid referred to in this article on the original patented process is the recipe / trade secrets that VRS hold and would provide to partners to manufacture with https://www.ulster.ac.uk/news/2012/january/revolutionary-breakthrough-by-ulster-scientists

- What Applications are 2D-Tech focused on?

Vertical Integration with the University of Manchester & National Graphene Institute

- 2D-Tech are a partner of the National Graphene Institute (NGI) at The University of Manchester. The University’s Graphene Business Director, James Baker, said: “The new production method that 2DTech have refined is an important step to producing high-quality graphene on an industrial scale. As partners of the National Graphene Institute, we are delighted to be supporting the advances 2D-Tech are making within graphene production and commercialisation. As partners, they have access to our critical mass of research expertise and work closely with us on how to take the commercialisation of graphene forward.” Versarien CEO Neill Ricketts commented: “Our technique is highly scalable, and we can also use our existing group resources to manufacture relatively large quantities of high quality graphene. We are now planning to commence production and by utilising our existing production facilities we expect to lower our graphene production costs.

- It is fair to say that where you see research by any of the following University of Manchester teams or leads, then Versarien via 2D-Tech are their commercial partner or are in pole position to license the IP from the University of Manchester (See link on projects and IP license opps for engineering and materials and see how are already directly attributable to Versarien or have potential in the future!) https://umip.com/current-technologies/our-technologies/

- Inkjet Printed Graphene E-Textiles – https://umip.com/current-technologies/our-technologies/inkjet-printed-graphene-e-textiles/

- Fuel Cells – https://umip.com/current-technologies/our-technologies/graphene-fuel-cell/

- Graphene Oxide water sensor – https://umip.com/current-technologies/our-technologies/graphene-oxide-based-water-sensor/

- Note that Versarien has focused on near term commercial graphene opps so you will see articles I’ve pulled across this that refer to a) ISO standards b) composites and carbon fibre etc … http://www.graphene.manchester.ac.uk/discover/the-people/

- Robert J Young – Professor of Polymer Science and Technology

- Research focus: Structure and mechanical properties of polymers and composites.

- https://www.research.mancheste…

- Research group: http://www.materials.mancheste…

- Ian Kinloch – Professor of Materials Science

- Research focus: Polymeric and carbon (graphene and nanotubes) and related nanomaterials.

- https://www.research.mancheste…

- Led the work with the ISO standards

- Aravind Vijayaraghavan – Lecturer in Nanomaterials

- Research focus: Graphene-based membranes and coatings.

- https://www.research.mancheste…

- – acts as an advisor and shown presenting side by side wit CEO

- Led the Innov8 rubber project – http://www.manchester.ac.uk/di…

- Kostas Kostarelos – Professor of Nanomedicine

- Research focus: Preclinical development of nanomedicine constructs based on novel nanomaterials of synthetic and biological nature.

- https://www.research.mancheste…

- Research group: http://www.nanomedicinelab.com…

- VRS partner via 2D-Tech on the 2D Health project he leads

- Robert J Young – Professor of Polymer Science and Technology

Below are the wider research team who 2D-Tech and VRS are affiliated with as a commercial partner but their research is typically not ready for commercial adoption so limited VRS newsflow on their projects but if you dig you can find links.

- Prof Sir Andre Geim – Professor of Condensed Matter Physics

- Research focus: Graphene and other two-dimensional materials.

- Prof Sir Kostya Novoselov – Professor of Condensed Matter Physics

- Research focus: Graphene and other two-dimensional materials.

- Vladimir Falko – Professor of Theoretical Physics, Director of the NGI

- Research focus: Theory of the physical properties of graphene and 2D materials; Nanoelectronics.

- Robert Dryfe – Professor of Chemistry

- Research focus: Electrochemistry of graphene and related 2D materials.

- Sarah Haigh – Lecturer in Materials Characterisation

- Research focus: Studying the structure and properties of nanomaterials.

- Cinzia Casiraghi – Professor in Nanoscience

- Research focus: Investigating the electronic, vibrational and optical properties of two- and one-dimensional materials such as graphene.

- Sasha Grigorenko – Professor of Physics

- Research focus: Graphene for optical applications with emphasis on graphene metamaterials and hybrid graphene plasmonic devices.

- Irina Grigorieva – Professor of Physics

- Research focus: The physics of graphene, in particular, the magnetic properties of graphene and its derivatives.

- Rahul Raveendran Nair – Professor of Materials Physics / Royal Society University Research Fellow

- Research focus: Graphene-based membranes and coatings.

- Roman Gorbachev – Royal Society University Research Fellow

- Research focus: Experimental condensed matter physics.

- Zhipeng Wu – Professor of Materials Science

- Research focus: Electronic properties and applications of graphene.

- Bruce Grieve – Director of e-Agri Sensors Centre

- Research focus: Sensors and ICT associated with agriculture and biotechnology.

- Lin Li – Professor of Laser Engineering

- Research focus: The use of graphene in welding.

- Aimin Song – Professor of Nanoelectronics

- Research focus: Nano-devices for energy harvesting and medical and security imaging.

- Alan Brisdon – Senior Lecturer

- Research focus: Fluorination of graphenes.

- Thomas Thomson – Professor in Computer Engineering

- Research focus: Magnetism in graphene and exploring the potential of 2D materials for spintronic applications.

- Peter Budd – Professor of Polymer Chemistry

- Research focus: Development of graphene-based membranes for a variety of applications.

- Ernie Hill – Senior Lecturer

- Research focus: Low noise magnetic sensing devices, graphene spintronic devices and patterned data storage media.

- University of Manchester also have a range of industry partners who fund research with the hope of creating commercial applications

- Strategic partner – Circa £1m/year over 3-5 years. 2-3 collaborative projects of significant size. Dedicated lab space within the NGI.

- Project partner – Circa £150k-£500k/year over 2-5 years. Collaborative project of varying size. Company to provide resource and have lab space in NGI.

- Many of the well-known brands below will have spent £ millions researching applications before they work with 2D-Tech to commercialise them so when we hear about collaborations in many cases e.g. Unilever who’ve had a strategic partnership with University of Manchester since 2014, they are moving into testing manufacturing, rather than testing applications (this is an enormous difference to most other graphene producers who announce research collaborations all the time).

Testing Applications for Customers

- Many graphene producers just sell a partner their bottle of graphene and then think their job Is done. What they don’t have is the complete operational set up to help partners to integrate graphene into their products and “prove” that they have the benefits

- As Versarien are now vertically integrated right into the heart of the University of Manchester & National Graphene Institute their customers don’t have to spend £100’s of millions on equipment for testing and application research / characterisation as VRS have access to it and the experts that use it.

- Before delivery of Nanene to a customer they have in the past had it certified via the University of Manchester & National Graphene Institute to show it is exactly what they say it is.

- Then they can provide proof that their Nanene product works as well as any of the applications and functionalisation they create for customers to provide them with “proof” that their products have picked up the Nanene benefits.

- Big companies value speed to market and competitive edge, so the risk of working with a graphene producer who can’t do this, and the end products not working means Versarien is now the global go to partner.

- This is a huge part of VRS credibility in the marketplace and guarantees continued support from the University of Manchester over and above any other partners

- The University of Manchester are very pleased with how things are performing – when due their cash payment said we want shares. They covered the outstanding payment at 19.14p per share when the share price was 10p. The University of Manchester are not daft they invented the stuff and know what it can do in the hands of VRS. http://ir1.euroinvestor.com/asp/ir/Versarien/NewsRead.aspx?storyid=13472620&ishtml=1

Shareholder relationship with the University of Manchester

- This is a huge part of VRS credibility in the marketplace and guarantees continued support from the University of Manchester over and above any other partners

- The University of Manchester are very pleased with how things are performing – when due their cash payment said we want shares. They covered the outstanding payment at 19.14p per share when the share price was 10p. The University of Manchester are not daft they invented the stuff and know what it can do in the hands of VRS. http://ir1.euroinvestor.com/asp/ir/Versarien/NewsRead.aspx?storyid=13472620&ishtml=1

The 2d-Tech team – described here http://www.2-dtech.com/about-us/

- Versarien have cherry picked the best talent to support them. You can also get a feel for what is coming and connecting the dots by what they specialise in!

- Kaylie Smith – Polymere scientist focused on the development of a novel synthetic route to a range of Polyaryletherketone (PAEK), including materials design, process development and scale-up, which resulted in a number of patent applications. PEAKs can be processed using all of the typical thermoplastic processes, such as injection molding, extrusion, compression molding, and transfer molding

- Applications from would include

- oil drilling components, such as seals, compressor rings, valve parts, gears, bearings, and wire coatings,

- chemical pump industry as it can stand temperature, stress, and has the corrosion resistance,

- automotive industry to make gears and thrust bearings in transmissions.

- medical devices like surgical implants, such as artificial hips due to its excellent resistance to hydrolysis because it does not break down when sterilized.

- Applications from would include

- Andrew Strudwick – Research scientist with strong backgrounds in graphene CVD production and characterisation techniques with experience in interfacing between industry and core research

- John Benson – Process development engineer from Ulster Uni who developed the original patented process, to support manufacturing of Nanene at scale and is now working on enhancing the process

- Arunprakash Arangaraju – Project Scientist. Has a PhD degree in Nanostructured materials in 2015 from the University of Manchester where the focus of his research was on production and applications of graphene and its composite. Strong background in the synthesis and characterisation of graphene-based nanomaterials and its polymer nanocomposites. During his time at 2-DTech, Arun has been involved in improving the production methods and developing new 2D material-based products, polymer nanocomposites, coatings and inks for various applications including aerospace, automotive, sport and printable electronics.

- Kaylie Smith – Polymere scientist focused on the development of a novel synthetic route to a range of Polyaryletherketone (PAEK), including materials design, process development and scale-up, which resulted in a number of patent applications. PEAKs can be processed using all of the typical thermoplastic processes, such as injection molding, extrusion, compression molding, and transfer molding

Cambridge Graphene Ink – http://www.cambridgegraphene.com/

Background to the VRS deal

- 2D-Tech MD pre the Versarien take over was Mark Shepherd the founder of £XAAR (inkjet printing) https://www.linkedin.com/in/mark-shepherd-b802a36/ .

- When Versarien took over 2D-Tech Mark went off to Cambridge to be CEO of Cambridge Graphene Ltd.

- HIGRAPHINK resulted in the creation of a spinoff called Cambridge Graphene Ltd

- Cambridge Graphene supplies novel inks based on graphene and related materials, using patented processes and develops graphene materials technology for licensing to manufacturers.

- Versarien get a call about a huge breakthrough on graphene ink so off the Cambridge they went as a known innovative company that would take the tech out of the Uni and keep the Uni involved so they benefit too. Versarien knew Manchester were struggling with ink so instantly recognised the massive breakthrough Cambridge had made.

- HIGRAPHINK (Highly Conductive Graphene Ink) –http://cordis.europa.eu/result/rcn/209392_en.html

- Originally, the roadmap of HIGRAPHINK (Highly Conductive Graphene Ink) consisted in demonstrating the viability of graphene as an additive for organic semiconducting materials, to drive proof-of-concept Organic light emitting diode (OLED) displays.

- The project was so successful at creating graphene with previously unthinkable properties that the University of Cambridge, decided to stick to readying it for commercialisation.

- HIGRAPHINK can now produce tens of thousands of litres per year where it could only hope for quantities in the range of milligrams daily before.

- Just two and a half years after the project was launched, six months after its end, HIGRAPHINK has resulted in the production of a material with a 100 % exfoliation yield, as opposed to the mere 1 % that could be achieved before the project team started their work. The new ink has a mobility 10 times higher than that of inks currently being used in OLEDs.

- Applications ranging from batteries to supercapacitors, displays, flexible electronics, optoelectronics, composites, coating or even medical devices.

- One of the applications he particularly believes in is the ink’s integration into batteries. Thanks to this, enhanced batteries with higher storage density and recyclability may be produced. This integration process is in fact already on track: Although Prof. Ferrari says it’s too soon to give out more information, he has already obtained further funding to bring HIGRAPHINK’s production technique to batteries.

Acquisition of Cambridge Graphene / Shareholder relationship http://ir1.euroinvestor.com/asp/ir/Versarien/NewsRead.aspx?storyid=13516986&ishtml=1

- Cambridge sold it for £170K cash, 1.45m shares in Versarien and kept a 15% share in the business.

- This is possibly the commercial deal of the century, however in exchange they invested in Neill and the Versarien teams ability to deliver long term value

- Versarien believes that the addition of Cambridge Graphene to its portfolio significantly increases the Company’s ability to advance its experience and expertise to commercialise the considerable market opportunities for graphene both in the UK and internationally.

- Material produced at both Manchester and Cambridge will be able to be used at either site in product development and for supply to customers and with both universities will be shareholders in the Company, positioning Versarien at the epicenter of the commercial development of graphene both in the UK and globally.

Business Focus areas

Supply proprietary Graphene inks and undertake development projects for customers in application areas including, but not limited to:

- High performance inks for conductive applications – Printed conductive inks for flexible electronics, antennas and a range of new products. Graphene inks can be cheaper, flexible, printable and better for the environment than traditional circuit board solutions.

- Graphene enhanced composites – Graphene has been shown to significantly modify the characteristics of composite materials. Exactly which form of graphene and functionalisation to use in specific applications is a development challenge for manufacturers. We undertake projects to define the recipe required for commercial products.

- Supercapacitors and batteries – Increased processing power means increased energy usage. Graphene’s applications in battery and capacitor technology will deliver huge advances across the low-power device market.

Cambridge Graphene Ltd Team

- Mark Shephard – MD: Over 25 years experience in the VC and angel backed technology start-up environment. He is joint inventor/founder of Xaar plc’s world leading ink jet technology, successfully led the technology’s early commercialisation through IP licensing and was involved in the Company’s listing on the London Stock Exchange in 1997. Prior to setting up Cambridge Graphene Ltd, Mark ran 2-DTech, a graphene technology spin-out from the University of Manchester.

- Dr Stephen Hodge – Principal Engineer. A Postdoctoral Research Associate and Teaching Fellow in Graphene Technology in the Cambridge Graphene Centre (CGC) at the University of Cambridge and bye-fellow in Chemistry at Murray Edwards college. PhD in Nanomaterials Chemistry at Imperial College London in 2012, joined the CGC at the University of Cambridge. His research interests cover the large scale development of nanomaterial-based dispersions, inks, coatings and functional 2d and 3d architectures for their incorporation into flexible electronics, sensor applications and energy storage/generation devices.

- Advisory Board – it is fair to say that after my research where the below stakeholders are talking about commercial graphene applications that its highly likely that Versarien are the partner via Cambridge Graphene Ink and or through their Nanene products as they collaborate closely with the University of Manchester

- Professor Andrea Ferrari – Technology Advisor. Professor of Nanotechnology and Royal Society Wolfson Research Merit Award Holder. He is the Director of the Cambridge Graphene Centre and Head of the Nanomaterials and Spectroscopy Group at the University of Cambridge Engineering Department and Nanoscience Centre. He is Professorial Fellow of Pembroke College.

- Dr. Felice Torrisi – Technology Advisor. University Lecturer in Graphene Technology, University of Cambridge and Schlumberger Research Fellow at Darwin College. Research interests cover the development of nanomaterial based dispersions, inks and coatings and their incorporation into polymer composites for printed flexible/stretchable and transparent (opto)electronics. Regular reviewer of major journals and invited speaker at national and international conferences in the field of printed/flexible (opto)electronics and nanotechnology. http://www.eng.cam.ac.uk/profiles/ft242

- Dr Tawfique Hasan – Technology Advisor. University Lecturer in Electronic Materials and Devices and a Royal Academy of Engineering Research Fellow in the Cambridge Graphene Centre, the Nanoscience Centre, and the Nanomaterials and Spectroscopy Group of the Engineering Department. He is a Title A Fellow of Churchill College, Cambridge.-

- Scan the 2014,15,16,17,18 publications in the links below to get an idea on new graphene applications coming to Versarien via the Cambridge Graphene Institute!

- http://hne.eng.cam.ac.uk – Dr Tawfique Hasan’s Hybrid nanomaterials Engineering research group engineer nanomaterials for printed photonics, (opto)electronics, sensing and energy.

- http://www-g.eng.cam.ac.uk/nms/overview.html – The Nanomaterials and Spectroscopy Group team is run by Ferrari and Torrisi and specialise in research into coating, optoelectronics and sensing applications.

Vertical integration with the Cambridge Graphene Institute

Cambridge Graphene Ltd get access to the research and partnerships that they have to develop applications for graphene and the ink products. https://www.graphene.cam.ac.uk/partners/partners/industry

Some special call outs as it relates to Cambridge Graphene Ltd and how are they going to get their graphene inks product to market by focusing on just 2 partners above.

Flexenable, Novalia and Cambridge Graphene Ltd have a very close relationship and are often seen presenting together e.g. At mobile world congress in 2016 http://www.eng.cam.ac.uk/news/graphene-takes-centre-stage-mobile-world-congress

- The Graphene Pavilion includes live demos and prototypes of many different properties and applications such as printable touch sensors (by the Cambridge Graphene Centre and partner Novalia), flexible displays (by the Cambridge Graphene Centreand FlexEnable) and a number of different flexible near-field communication antennas, sensors and ultra-fast photo receivers (also produced in collaboration with the Cambridge Graphene Centre). Dr Stephen Hodge and Dr Nicolas Decorde will present several of the demos and interact with visitors and media throughout the week.

Novalia

http://www.novalia.co.uk/ use ordinary printing presses to manufacture interactive electronics, which combine touch-sensitive ink technology and printed circuits into unique and cost-effective products … watch the ted talks here to have your mind blown away! http://www.novalia.co.uk/talks/

- A low-cost, high-speed method for printing electronics using graphene and other conductive materials could open up a wide range of commercial applications. Oct 2015

- “We are pleased to be the first to bring graphene inks close to real-world manufacturing. There are lots of companies that have produced graphene inks, but none of them has done it on a scale close to this,” said Dr Tawfique Hasan of the Cambridge Graphene Centre (CGC), who developed the method. “Being able to produce conductive inks that could effortlessly be used for printing at a commercial scale at a very high speed will open up all kinds of different applications for graphene and other similar materials.”

- Currently, printed conductive patterns use a combination of poorly conducting carbon with other materials, most commonly silver, which is expensive. Silver-based inks cost £1000 or more per kilogram, whereas this new graphene ink formulation would be 25 times cheaper. Additionally, silver is not recyclable, while graphene and other carbon materials can easily be recycled.

- The new method uses cheap, non-toxic and environmentally friendly solvents that can be dried quickly at room temperature, reducing energy costs for ink curing. Once dry, the ‘electric ink’ is also waterproof and adheres to its substrate extremely well. The graphene-based inks have been printed at a rate of more than 100 metres per minute, which is in line with commercial production rates for graphics printing, and far faster than earlier prototypes. http://www.cam.ac.uk/research/news/new-graphene-based-inks-for-high-speed-manufacturing-of-printed-electronics

- Scalable 100% Yield Production of Conductive Graphene Inks – Feb 2017

- The new microfluidisation process to exfoliate graphene flakes from graphite converts 100% of the starting graphite material into usable flakes for conductive inks, avoiding the need for centrifugation and reducing the time taken to produce a usable ink. Inks produced using this method have already been commercialised via a University of Cambridge spin out company, Cambridge Graphene, which was recently acquired by engineering solutions company Versarien.

- Conductive inks are useful for a range of applications, including printed and flexible electronics such as radio frequency identification (RFID) antennas, transistors or photovoltaic cells. The advent of the internet of things is predicted to lead to new connectivity within everyday objects, including in food packaging. Thus, there is a clear need for cheap and efficient production of electronic devices, using stable, conductive and non-toxic components. These inks can also be used to create novel composites, coatings and energy storage devices.

- The inks are also supplied to Novalia, UK for use in their interactive touch-based printed electronic demos. Chris Jones of Novalia said “For viable marketable applications, the materials need to be cost effective, easy to handle and show consistent performance. We ran these inks on ordinary industrial screen printing equipment without modification and achieved consistent results, printing hundreds of interactive demonstrators for Mobile World Congress. This is a very exciting point – a critical juncture between the laboratory and the public.” https://www.graphene.cam.ac.uk…

- Researchers have successfully incorporated washable, stretchable and breathable electronic circuits into fabric, opening up new possibilities for smart textiles and wearable electronics ranging from personal health and well-being technology, towearable energy harvesting and storage, military garments, wearable computing and fashion. Nov 2017

- Demonstrated how graphene can be directly printed onto fabric to produce integrated electronic circuits which are comfortable to wear and can survive up to 20 cycles in a typical washing machine. The printed components are flexible, washable and require low power, essential requirements for applications in wearable electronics. The circuits were made with cheap, safe and environmentally friendly inks, and printed using conventional inkjet printing techniques

- “Turning textile fibres into functional electronic components can open to an entirely new set of applications from healthcare and wellbeing to the Internet of Things,” said Torrisi. “Thanks to nanotechnology, in the future our clothes could incorporate these textile-based electronics, such as displays or sensors and become interactive.”http://www.cam.ac.uk/research/news/fully-integrated-circuits-printed-directly-onto-fabric

- This is the pdf that shows Nokia testing Versariens Cambridge Graphene ink in Rfids – https://graphene-flagship.eu/Lists/Deliverables/D8.6.pdf

- The timing fits in nicely with the Global Apparel Brand who announced a collaboration on 8thJanuary with Versarien on the incorporation of graphene into fabrics and assess its suitability for inclusion in high performance sportswear! CEO in Vox market podcast said it took 6 weeks from initial contact to collaboration! http://www.londonstockexchange…

FlexEnable – http://www.flexenable.com/

Pioneered an industrially-proven organic transistor technology platform for flexible displays and sensors on plastic that bring transformational advantages to products including shapeability, lightweight, thinness and durability while providing a path to low cost. There are huge numbers of applications from automotive, wearable and mobile technology, healthcare, biometrics and digital signage that the FlexEnable platform can support – http://www.hvm-uk.com/uploads/cgd15cain.pdf – See slides 13,14,15 for how graphene enhanced Flexenable applications

- Flexenable spun out of Plastic Logic and focussed on the exploding markets for wearables, new mobile devices and distributed, flexible sensors for IoT applications. Flexenable is based on Plastic Logic’s full technology and patent portfolio, but will independently provide expertise, technology and products to system builders, device makers and product companies to enable innovative, volume products. They now seem to be scaling up to meet customer demand http://www.flexenable.com/newsroom/business-news/the-launch-of-flexenable/

§ Truly and FlexEnable sign License Agreement to bring low-cost, scalable flexible display production to China – http://www.flexenable.com/newsroom/business-news/truly-and-flexenable-sign-license-agreement-for-flexible-display-production/

§ FlexEnable collaborates with Merck to enable novel display shapes using conformable plastic LCDs – http://www.flexenable.com/newsroom/business-news/flexenable-collaborates-with-merck-to-enable-novel-display-shapes/

§ Plastic Logics owner is RUSNANO a Russian state owned company that invests a $4billion fund that implements state policy for the development of the nano industry in Russia, acting as a co-investor in nanotechnology projects, which have substantial economic or social potential. They invested $171m to take full ownership of the company. http://en.rusnano.com/about Novaled – owned by Samsung. Plastic Logic & Novaled Collaboration – 6 February 2014 – Plastic Logic, the leader in the development and industrialisation of flexible organic electronics, and Novaled, a leading company in organic electronic materials and technology for OLED applications, announce a partnership which will transform and accelerate the market for flexible and wearable displays. Novaled’s majority owner is Samsung Cheil Industries part of Samsung http://www.novaled.com/news_press/newsitem/plastic_logic_and_novaled_partner_to_demonstrate_a_world_first_for_displays_and_open_a_new_frontier/

Scalable VRS product technology and manufacturing

Versarien have also been clear that they would only build manufacturing capacity once the demand is there because depending on the type of application a customer needs, you may need a different graphene manufacturing process / fuctionalisation process to support it

- CPI tenders – the tender was based principally on the quality and specification of the graphene to be supplied with additional marks awarded for price and delivery and there was 100% success by Versarien. CPI rejected all other graphene suppliers around the world many of whom couldn’t even meet the initial spec and went for Versarien graphene in every case applied. Versarien will be supplying up to 1.2 kilograms of graphene in a variety of forms, including the Company’s proprietary brand, Nanene, Graphene Ink and Boron Nitride (white graphene) to the CPI .http://www.londonstockexchange…

Cambridge Graphene

Uses a scaleable production process for its graphene ink, developed at the Cambridge Graphene Centre, University of Cambridge. The process allows for a range of ink formulations to be manufactured in order to meet the requirements of different printing methods and substrates. Currently, all Cambridge Graphene inks are aqueous, environmentally friendly and non-toxic.

- At a shareholder presentation in May 2017 that a number of the ADVFN crowd went to (Superg1, Compoundup) Professor Ferrari claimed that for a modest investment we can do 100,000 litres per year (100 tonnes of ink).

- The CEO mentioned that they were 6 months ahead of the game, well this funding from Innovate UK for £68k from July 2017 to do the following: Cambridge Graphene Ltd – Upscaling novel microfluidisation for repeatable, low-cost creation of quality graphene ink

- This project aims to validate a pilot scale production of graphene ink from proven novel, repeatable, microfluidisation process at lab-scale. Inks produced to date show market leading sheet resistance, can be used in commercial printing processes at up to 25 times cheaper than metal alternatives. As production chamber size increases, the physics of the system alters (longer particle residency, travel time) delivering a challenge to repeating lab-scale outputs. Further research into novel feedstocks & improved outputs (larger flakes, lower sheet resistance, tailored viscosity) is to be investigated.https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/643693/Emerging_and_Enabling_Technologies_Round_2_-_Up_to_12_Months_-_Competition_Results.pdf

Unlike Nanene it feels like they are able to achieve high concentrations of ink in the manufacturing process, so may not need to do local manufacturing (with associated JV’s & licensing) and instead Versarien can control all manufacturing and shipping of inks to partners.

2D-Tech – Nanene

Versarien has been clever in buying Total Carbide that Neill knew from his previous job at Electron Technology (£EKT). Not only has he turned it into a more profitable faster growing business since he owned it, but he realised that their core manufacturing capability was “grinding (sometimes known as milling)” to create c. 30 tonnes of powder that they used in their hardware products. This knowledge has helped them to accelerate manufacture and functionalisation of Nanene which uses a patent‐protected, mechanised exfoliation process (often known as grinding).

Nanene needs to be produced locally where it is going to be incorporated into other materials & products. Due to its lightness 1 tonne of Nanene would fill 38,000 oil drums … you don’t want to compress it or you end up with graphite!

- ‘The machine’ Versarien uses to produce Nanene means they can have a modular set up, thus set it up anywhere in the world in quick time.

- They originally had a machine that could make 100 grammes per day. There are bigger machines than the tenfold version (1 kg per day) that they have purchased with the funds raised from the recent share placing in 2017.

- If Versarien hit customer demand higher than 350 kgs in the next 12 months then it will be a fantastic problem to have e.g. if it sells for £25 per gram = £8.75 mill, £50 per gram = £17.5m so there is a fast payback

- There are likely optimisations they can make on the amount of Nanene they can produce from a single machine e.g. double shifts but for now if we estimate 1kg of Nanene per day per machine we have room for upside

- If a customer with really big demand comes needing loads they can potentially licence Nanene and do it themselves with royalties back to Versarien and just use many of the machines to produce more.

Now that VRS can manufacture Nanene and Inks at scale and are viable on costs a large customer can’t

- block such a product by buying up all supply – (See example Apple buying all IQE VSCEL wafer capacity for next 2 years to have USP in marketplace with Face ID)

- have exclusivity – there are over 100 companies chasing it desperate to get ahead of the game … and now whole countries

- buy Versarien – I believe that this is off the table due to wanting to keep the Graphene Flywheel going and continued stakeholder support including the UK government which leads to JV and licensing deals (see China JV!).

What currently is the best way to gain competitive advantage for your company and products with graphene?? Get moving sharpish and get Nanene and Graphene inks into your products first! See China!!

International Manufacturing Expansion

LOI for China JV to manufacture Nanene

Versarien signed a Letter of Intent (“LOI”) to establish a graphene manufacturing centre in China with the Shandong Institute of Industrial Technology Fund, Jinan Qing Na Material Technology Co Ltd and Jinan Innovation Zone Administrative Committee with the view to establishing the “China-UK Jinan Graphene Industrial Park” in the Jinan Innovation Zone, Shandong Province, China

- 1st stage the establishment of a 100,000 square foot manufacturing facility to produce and sell Versarien’s proprietary Nanene few layer graphene nano-platelets (this is roughly the size of two football pitches!).

- 2nd stage objective is the establishment of the first Chinese graphene industrial park, the “Jinan Graphene Valley” including a graphene research institute with funding coming from the joint venture partners.

- The total project cost is £55 million

- How it happened – Oct 2015 University of Manchester received president Xi of china – said wanted to collaborate with UK around graphene

- Met Jinan team in November 2017 – had requirement they couldn’t fulfil (See DTI tender offer!), want to get into graphene in a big way, want a player with all due diligence, data reliability, verification all done = VRS

- Presentation at University of bath, then dinner 2 days later, then official invitation to come out to China as guests of Chinese govt and Shandong province, then LOI 4 to 5 weeks from start to finish!

- Govt official Chinese graphene market by 2023 worth $200 billion – Chinese govt running at hyper speed and can influence demand for graphene (See belt & road, Electric cars!)

- Shandong want to create China graphene valley (the new Silicon Valley!)

- Shandong contains large amounts of graphite resources

- VRS at the centre, backed by Chinese govt and as a partner

- Shandong want to create China graphene valley (the new Silicon Valley!)

- Speed is key – VRS could have invested to create manufacturing, however time and money and risk

- Chinese have done their graphene due diligence and found no local players that meet standards required, hence deal with VRS and Nanene

- Need to establish manufacturing close to customers using it graphene doesn’t travel as so light 1 tonne = 38,000 oil drums!

- VRS now under pressure to get operational and get live in July 2018 live producing Nanane in china!

- Can meet Chinese demand as the manufacturing process is modular and each step up the kit ladder gives exponential growth for production very cheaply. Just repeat the modules that are known to work and multiply them, hence the production has no limit.

- From the module point 100 tonnes is a walk in the park – A 100,000 square ft factory could have 250 of Versariens existing machines churning out graphene at 375 kg’s p.a each making 93.7 tonnes per annum … this is before they even test and launch the next scale up machine that could produce tens of KG’s or even tonnes per day (which they are already investigating)

- JV set up

- China invest to cover for all costs of building and manufacturing – The building is already built!

- VRS have no costs and will be paid a royalty, profits would be split demanding on the percentage shareholding which is being negotiated. VRS will supply equipment (machines and chemicals) and either lease it or sell it to Chinese (and likely get them to pay upfront).

- The negotiation setting up a JV is with a province not a commercial company per se. Could the JV ascribe all production and sales of Nanene to Versarien with the Chinese end responsible for sales? That way China gets the added benefit from lighter end materials and VRS gets all the profit from Nanene and dictates the price.

- Business plan is being written by Chinese on amount they want to produce to meet local demand (huge opp with electric vehicles)

- VRS changed it to a non binding LOI so they could fully digest the deal but as reported on Sky news, it looks like Versarien are ready to get it signed during Theresa May’s trip to China to meet the President w/c 29th Jan 2018! https://news.sky.com/story/downing-street-races-to-clinch-deals-ahead-of-mays-china-visit-11222951

- IP – do we trust Chinese?

- Worked closely to choose right partners, Party secretary 2 down from president (his scientific advisor) and given categorical promise that IP protected. Several internal measures to protect them

- Patent protection, company know how, supply of machines, chemicals, everyone wants to make it work.

- Graphene great but another 2,000 2D advanced materials … research centre in UK, manufacturing next gen 2D materials, if we don’t like what we see then China won’t see other 1999 2D materials. Therefore VRS must work really hard to keep up with pipeline of new developments to keep interest.

- Establishing Hong Kong base

- License IP for similar deals in similar countries, so once set up its easy to replicate e.g. Japan, South Korea, Taiwan etc …

- UK govt invested heavily in these technologies via University of Manchester, University of Cambridge and now VRS getting opportunities to export this tech and exporting globally

- Impossible to quantify value of this deal at this stage to Versarien or UK PLC

- Benefits: Export value, high quality, highly skilled jobs in UK, local manufacture but do outside UK where appropriate

- Challenge: How to grow quickly, satisfy demand for these products

- Status: Can satisfy demand in china with this deal – no shortage of money, or factories to manufacture Nanene to supply the demand in China domestic market where many of the worlds products are manufactured!

Background – Why do China want Graphene?

- https://www.youtube.com/watch?v=YOvU5l9i2KU – Really good presentation to understand how China has grown to where it is via one off productivity improvements and mainly through the imitation of existing technologies. You will see on 14 mins that the key to maintaining china growth is to focus on innovation in new technologies hence the major Chinese govt investment to rebalance the economy and change in culture and global partnerships in relation to IP (Think Japan in the 1980s who went through a similar change).

Background – What types of demand do they have?

- Belt and Road Initiative (BRI)

- The aim of the $900 billion scheme, is to kindle a “new era of globalization”, a golden age of commerce that will benefit all. The Chinese government says it will ultimately lend as much as $8 trillion for infrastructure in 68 countries covering 65% of the global population and a third of global GDP, according to the global consultancy McKinsey. https://www.weforum.org/agenda/2017/06/china-new-silk-road-explainer/

- The Belt and Road Initiative and the Future of Globalization – Xi Jinping’s signature policy is about more than just infrastructure https://thediplomat.com/2017/10/the-belt-and-road-initiative-and-the-future-of-globalization/

- UK – China Fund

- David Cameron is vice chairman of the UK-China Fund a $1bn investment fund set up to back China’s Belt and Road infrastructure initiative. The state-endorsed fund will be led by private institutions in UK and China. Douglas Flint, the former group chairman of HSBC, as the UK Treasury’s Belt and Road envoy, as well as the establishment of as new UK-led BRI expert board to guide investment.

- http://www.telegraph.co.uk/news/2017/12/16/david-cameron-set-750m-uk-china-investment-fund/

- Having Cameron Lead the UK-China Fund Is Good for Britain and China – https://thediplomat.com/2017/12/having-cameron-lead-the-uk-china-fund-is-good-for-britain-and-china/

- My Opinion – Cameron and Osborne had the determination to make sure the graphene breakthrough born in Manchester ended up with the Unis and the UK benefitting from it so they spent millions to build the National graphene institute (£60 million), funding research at UK universities, as well as engaging with a little known advanced materials company. This became especially important when the Chinese president visited the UK in 2015, as Neill Ricketts was at the NGI and met both him and Cameron to discuss their graphene progress … that is where the seeds are sown. Neill has since met DC a lot as well as grown very strong contacts in government … and now DC has a big cheque book!

- We now know that CRRC Changchun Railway Vehicles, a leading Chinese train car maker, announced that it has developed a prototype of the world’s first subway train made of carbon fibre.

- CRRC says its composite prototype is more durable and requires less energy than traditional metal cars. It is also believed to be 35 percent lighter due to its use of carbon fibre. http://www.crrcgc.cc/en/g7389/s13996/t290248.aspx

- Chinese Bullet trains – May 2017

- China is developing a new generation of trains capable of reaching 400 km per hour. The high-speed trains will be part of the so-called Belt and Road Initiative to boost economic ties with other countries.

- “We will apply new materials in the research and production of the future high-speed trains, such as carbon fibre and aluminum alloy, which will help to reduce weight and enhance energy efficiency,” said Qiao Feng, a senior engineer at the CRRC Changchun Railway Vehicles, a subsidiary of China Railway Rolling Stock Corporation. He added the new trains would be able to reduce energy consumption per passenger by ten percent. They are expected to promote regional connectivity and create new businesses for China and overseas economies. http://www.chinadaily.com.cn/china/2017-05/03/content_29175985.htm

- China-Britain Business Council (CBBC) is the UK Governments Department for International Trade’s chosen partner in China to deliver trade services – They advertised the below:

- China – Graphene R&D and application technology wanted by a Shandong company – Expiry date 30 June 2017

- A research company is seeking the expertise and technology from the UK, ideally in an advanced state close to industrial applications.

- The company can offer R&D opportunities which will include other leading research and academic institutions in China.

- It is a public company with multiple businesses.

- https://opportunities.export.great.gov.uk/opportunities/china-graphene-r-d-and-application-technology-wanted-by-a-shandong-company

- My Opinion – Note how the DTI act as a local lead generation for companies like Versarien … this spec feels a lot like CRRC Changchun Railway Vehicles opp above?!

- The Beijing Institute of Aeronautical Materials (BIAM) and the National Graphene Institute (NGI) at The University of Manchester will carry out a five-year collaborative research project which plans to deliver lighter, better performing aircraft and high-speed trains. http://www.manchester.ac.uk/discover/news/graphene-partnership-could-deliver-lighter-planes

- Professor Robert Young, who leads the research project at The University of Manchester, said: “BIAM have a rapidly developing research programme on graphene composites and we are looking forward to pooling our expertise with them to facilitate the use of these materials in aerospace applications”.

- Graphene has been included in the latest Chinese five-year plan and the country is starting to develop its domestic civil aerospace industry and expect to improve their expertise on materials.

- My Opinion – Professor Robert Young, is the guy that did the tests on Nanane in carbon fibre and was raving about the results (50% stronger with on 1% loadings). It sounds like the Chinese rail network and subway network is changing entirely to carbon fibre carriages and will use graphene to make them lighter and no corrosion and will likely to expand graphene to all plastic and composites within the train to make them lighter and stronger. This could be a big reason for the sudden interest by China in Nanene and the need to scale up graphene production so rapidly.

China is very serious about Electric Vehicles

- China Government are driving graphene demand with their electric cars target

- 22 Sept 2017, China’s Ministry of Industry and Information Technology (MIIT), which oversees the auto industry, proposed a Corporate Average Fuel Consumption (CAFC) and New-Energy Vehicle Credits designed to improve the fuel efficiency of traditional-fuel vehicles, as well as to promote the deployment of New Energy Vehicles (NEVs) in China. China’s proposal would require automakers to produce fleets with a Corporate Average Fuel Economy of 42 miles per gallon by 2020, and 54.5 mpg by 2025, with a goal of generating a market for more than five million new-energy cars in the 2016 to 2020 period.

- Production quotas will be enforced through a credit-score system in which automakers earn super credits for the production of NEVs. Companies that fail to hit their targets will be compelled to purchase credits from companies with excess credits or be subject to MIIT-imposed penalties

- In order to encourage the purchase of EVs, China’s Central Government currently provides subsidies of from $3,030 to $6,666 per vehicle, depending upon vehicle range. Most local governments add from 15% to 50% to that amount. For an EV with a range of 250 kilometers (150 miles) or greater, the subsidy in Beijing amounts to $10,000 per vehicle. In addition to subsidies, many cities provide favourable policies such as the assured issuance of a vehicle license and increased access to HOV lanes e.g. in Beijing in any given month, 3 million applications might be received for the 3,000 available new vehicle licenses, with the remainder going into a lottery pool. Buyers of Electric Vehicles, however, are exempt from this process and assured of receiving a license.

- Subsidies scheduled to be phased out in 2021, therefore greater price parity between Electric Vehicles and internal combustion engine cars will be necessary. Because it is questionable whether battery costs will fall sufficiently to offset the loss of the consumer subsidy, automakers in China may be forced to lower prices — and profit margins — in order to sell the EVs they will be required to manufacture in China under the new rules.

- Sales of EVs in China are forecasted to be 680,000 units in 2017, with a 46% increase projected for 2019. UBS, a global securities firm, estimates that global EV sales will reach 14.3 million units in 2025, with China accounting for 4.8 million of the total, so China is well on its way to meeting its EV targets.

- https://www.forbes.com/forbes/welcome/?toURL=https://www.forbes.com/sites/jackperkowski/2017/10/10/china-raises-the-bar-with-new-electric-vehicle-rules/&refURL=https://www.google.co.uk/&referrer=https://www.google.co.uk/

- My Opinion – What this really means is the government has set the demand and the Chinese car manufactures will be desperate to not just enhance batteries (see below the wider progress Versarien have made here), but also the easy wins of using graphene enhanced composites to lightweight the NEV’s so it can travel further.

- China: Huawei Announces Breakthrough In Its Research In Graphene-Assisted Li-ion Battery With Doubled Lifespan

- The new graphene-based heat-resistant technologies allow Li-ion batteries to remain functional in a temperature 10 degrees Celsius higher than the existing upper limit. The lifespan of the graphene-assisted Li-ion batteries will also be twice as long as ordinary Li-ion batteries

- Back in 2015, Huawei already announced its co-study program on the application of graphene with Manchester University, devoted to the development of a next-generation technology to consumer electronic products and mobile communication equipment’s. The graphene-assisted Li-ion battery will also enable electric cars to drive extra miles and drones to fly safely under high temperatures. http://www.mondaq.com/china/x/561872/Patent/Huawei+Announces+Breakthrough+In+Its+Research+In+GrapheneAssisted+LiIon+Battery+With+Doubled+Lifespan

- A new solar highway in China perfectly captures its clean-energy ambitions

- China is billing the project as the world’s first photovoltaic highway. The Jinan stretch is designed for both electricity generation and public transport and could handle 10 times more pressure than the normal asphalt variety and in a year generate 1 million kWH of electricity, which will be used to power street lights and a snow-melting system on the road. It’s also designed to supply power to charging stations for electric vehicles, should those be added in the future.

- The road cost around 3,000 yuan ($458) per sq m, significantly higher than regular streets. Still, the project signals China’s solar-power ambitions. Last year the country became the world’s top solar-energy producer, boosting its photovoltaic capacity to around 78 gigawatts, and it’s aiming for 105 by 2020. https://qz.com/1166975/a-new-solar-highway-in-china-perfectly-captures-its-clean-energy-ambitions/

My Opinion – By connecting the dots the transformational opportunity for Versarien starts to makes sense.

- This deal is at Government level as its monetising UK university IP, so any messing around with Nanene and they will have the door slammed shut on then for the other technology and 2000 advanced materials we are already working on.

- Rather than fight China work with them and you can become very rich. The Chinese government need direct access to the coming advanced materials revolution and the UK is the lead. China want to be the innovative technology power with first mover advantage and not constantly 5 steps behind all the time making cheap low quality copies

- This deal means that now that Versarien via their unique shareholder relationships with University of Manchester have access and knowledge of the breakthroughs going through then their JV partner China is now vertically integrated into the best facilities in the world for advanced material research and manufacturing.

- The biggest disruptor in the world economy now has the most disruptive material enhancing all of the products that they create and sell to the world.

- What will drive rapid growth for graphene and Versarien is disruption like China forcing all other counties, industries and companies to move fast or struggle when game changing products launch. The China JV example will be rolled out worldwide

Which countries are next?!

Versarien are looking at doing other deals like this and have already met with key players as part of their world tour with the DTI throughout 2016

- South Korea – VRS have strong links set up by DTI to Korea with Samsung

- The Samsung Advanced Institute of Technology (SAIT) has successfully synthesized a now-patented “graphene ball” that can be used to make lithium-ion batteries last 45 percent longer and charge around five-times faster, it has been revealed. The SAIT has been behind a number of commercialized technological breakthroughs, including the development of the cadmium-free Quantum Dot materials that are being used in Samsung’s high-end—and flagship—QLED TVs. https://www.sammobile.com/2017/11/27/%E2%80%8Bsamsung-develops-patents-graphene-ball-speed-charging/

- India, Japan and Mexico were all visited by Versarien with the Department of Trade & Industry on trips during 2017

- Tata Steel seems to be leading the way in India working with Indian Universities. https://www.nationalgrapheneassociation.com/news/tata-steel-eyes-commercialisation-graphene/

- Tata Steel Europe R&D also have a scientist embedded in the Cambridge Graphene Centre – I assume as they are interested in the Inks products to integrate with steel instead of the graphite they use today https://www.graphene.cam.ac.uk/people/dr-sai-shivareddy

- USA – Startup Europe Comes to Silicon Valley (SEC2SV) – Versarien were one of 2 UK companies invited out there with only 12 from Europe for that event. http://www.londonstockexchange…

- Since then they have opened an office in Palo Alto in California, USA, in Nov 2017 to handle sales enquiries, but will be interesting to see how that develops with US government as they are significantly behind Europe with their graphene research and production capabilities.

VRS Application and Product Development

This is the key USP that VRS have in the marketplace and why the University of Manchester and University of Cambridge see such value in Versarien as they are proving that they can take things from the lab into the marketplace.

Versarien is rapidly establishing itself as the go-to supplier of high quality graphene and other potentially industry disruptive 2D materials as they can supply it anyway you like.

- Have built a good portfolio of data to show global players and institutions

- After lots of dedicated hard work they are now beginning to reap the benefits

- Talk from position of authority and strength when talking to companies

Enabling and Dispersion Capabilities

Many Graphene producers don’t have any product development or dispersion techniques and can’t advise customers who are clueless on how to do it. They just provide the bottle! If their graphene won’t work in the customers application, then they can blame dispersion the techniques used by the partner.

- VRS have the ability to manufacture their own products

- Using Versarien’s existing graphene manufacturing capabilities, www.aaccyroma.co.uk (AAC) will have the ability to produce graphene-enhanced plastic products

- AAC provides the option to produce whatever a customer needs to test / trial and perhaps a complete supply line. There are big costs involved and down time in setting up industrial production lines to fit something that may be under consideration.

- AAC is simply an option supply actual parts should end users want it EG like JLR.

- Provide the raw Nanene product for the partner to mix

- If you don’t know how to disperse and mix it with your products they will simply use their unique research via University of Manchester, University of Cambridge to pre-mix in your desired master batch be it resin liquid or something else and then prove how it performs in your product / application.

Depending on the type of application a customer needs, you may need a different graphene manufacturing process and enabling process to support it

- 2D Tech in some cases don’t need enablers for Nanene and it mixes freely directly into products.

- Many tech players in the graphene space claim that you need to use their “tech to enable” graphene before it could be used e.g. Haydale which is incorrect.

- There will be cases where enabling will be need on the millions of combinations that exist for graphene. The costs involved to go through tests and time involved are huge and there may be no improvement.

- Market Issue: Very limited data worldwide where producers or users actually show verifiable independent data to show how their graphene has enhanced a product.

- VRS stands head and shoulders above the others right now as the data is out there that Nanene provides huge gains well beyond thought possible why would industry waste years at this time trying to tweak it. As a result the basic market right now is high quality Graphene that actually work which is what VRS are all about

Versarien Product Capabilities

VRS don’t talk openly about markets with huge potential like batteries and instead focus on which opportunities are going to produce cashflow fastest and at scale in near term to fund future expansion.

- They have it all recorded in presentations on their strategy for what functionalisations they develop – Tier 1 being the here and now and reduced focus on Tier 3 future tech but keeping a finger on that pulse to keep an eye on opportunities.